Rennet

شنبه ، 1 شهریور 1399

Coagulation of milk by rennet initially occurred probably by accident, as warm milk was stored in sacks made from the stomach hides of ruminant animals, which contained some residual proteinase.

Rennet may be considered as a functional enzyme preparation that is effectively and naturally adapted to the purposes of cheese making.

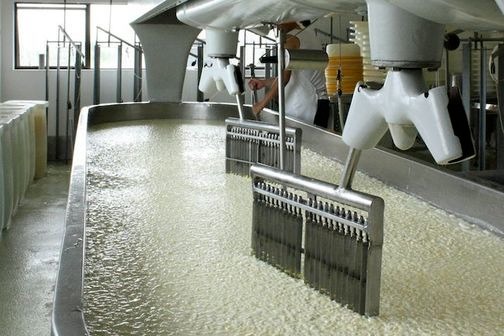

Coagulation of milk with rennet is the first step in the production of any rennet coagulated cheese variety. Traditionally, for the production of rennet-coagulated cheeses, calf rennet, obtained from the fourth stomach of young calves, has been used. Such rennets contained two primary proteolytic enzymes, namely chymosin (~80%) and pepsin (~20%). Increased cheese production and demand for beef worldwide during the 20th century resulted in a shortage of calf rennet; hence, substitutes for calf rennet were sought.

The rennets of non-animal origin are intended for productions that prevent, for legislative, religious, technological, or even solely economic reasons, the use of normal rennets of animal origin.

Rennet coagulation has several important advantages over acid coagulation; these include faster coagulation (i.e., minutes) compared to the slower rate of acid development (i.e., hours) required by starter cultures to coagulate milk for cheeses such as Cottage cheese (in contrast, milk coagulates very rapidly when acid is added directly). Renneted milk gels also undergo much more syneresis than do acid milk gels, which helps to produce cheeses with lower moisture levels.

Rennet coagulation of milk is a two-stage process, where the primary stage involves enzymatic hydrolysis of the micelle-stabilising κ-casein, and the secondary stage involves the aggregation of micelles, in the presence of calcium ions, at a temperature >20°C. There is an overlap between primary and secondary phases of rennet coagulation, the extent of which depends on temperature, pH and protein content.

The primary stage of rennet coagulation involves the enzymatic hydrolysis of the Phe105-Met106 bond in κ-casein, yielding the N-terminal fragment para-κ-casein (f1–105 – referred to as para-κ-casein), and the C-terminal fragment κ-casein (f106–169 – referred to as the caseino-macropeptide – CMP); CMP from glycosylated κ-casein is often referred to as glycol-macropeptide (GMP).

When ~85% of κ-casein is hydrolysed, the secondary stage of rennet-induced coagulation of milk commences. The enzymatic hydrolysis of κ-casein during the primary stage of rennet coagulation results in considerable alterations in the properties of the casein micelle. Perhaps the most significant in terms of rennet-induced coagulation is the reduction in the net negative charge on the casein micelles, by ~50%.

Factors that influence rennet-induced coagulation of milk

pH

The pH of the milk strongly influences the rennet-induced coagulation of milk. A reduction in milk pH to a value in the range 6.6–6.0 results in a reduction in the rennet coagulation time (RCT) of milk. Furthermore, a reduction in milk pH also reduces the degree of κ-casein hydrolysis required for the onset of gelation. The rate of increase in the firmness of the coagulum of bovine milk is also enhanced by reducing the pH, probably due to solubilisation of CCP. At a pH <6.0, the strength of the coagulum is reduced, probably due to excessive solubilisation of CCP, which is essential in maintaining micellar integrity.

Calcium concentration

The concentration of calcium (i.e. in the form of CaCl2) also has a significant effect on RCT. Calcium

plays an indirect role in primary hydrolysis of κ-casein by reducing pH, which can enhance the activity of the enzyme. Furthermore, addition of calcium can reduce the degree of κ-casein hydrolysis required for the onset of coagulation and increase the rate of development of firmness of the coagulum through neutralisation of the net negative change and the formation of calcium bridges.

Protein content

Casein content of milk is negatively correlated with the RCT. The rate of aggregation increases and coagulation occurs at a lower percentage of hydrolysed κ-casein.

Enzyme concentration

Processing treatments